MtronPTI High Power Handling Space Level Component and Sub-Assemblies Design and Testing Capabilities

MtronPTI has over 125 design wins across satellite platforms and manned spacecraft. With expertise supporting LEO, MEO and GEO applications, MtronPTI has a well-established team and a proven track record to meet demanding space requirements.

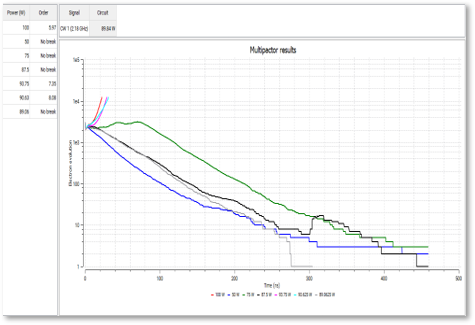

With the evolving need for high-power space-level transmitters, high-power handling space-level RF components and sub-assemblies are instrumental for mission success. The performance of these devices used in orbiting satellites are significantly different compared to how they perform at sea level due to phenomena like multipaction. Some space-level applications require both continuous operation performance in outer space as well as performance during the assent to space, i.e. undergoing a pressure change from ambient to 1 x 10-5 Torr over temperature to avoid corona discharge. Understanding the capability of the high-power handling RF components and sub-assemblies during the assent to space and in orbit is critical for successful space missions. Detecting potential risks at an early stage prevents a catastrophic failure.

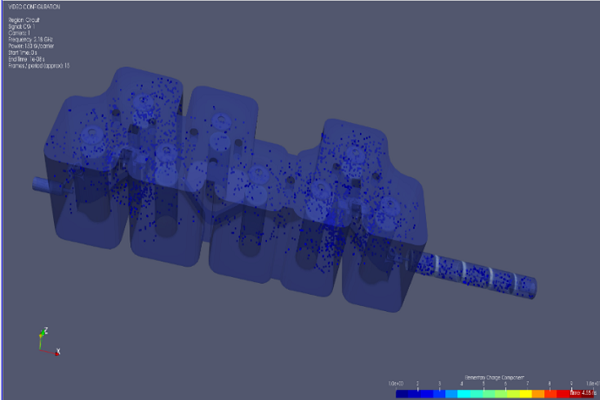

In addition to existing in-house testing capabilities1 for testing space level components and RF assemblies, MtronPTI has invested in simulation tools like Spark3D™ to maximize power handling capability under vacuum in the early stages of the design process. MtronPTI has also invested in a altitude (hypobaric) chamber to support high power handling RF components and sub-assemblies testing. The incorporation of an altitude test chamber enables MtronPTI to adjust the temperature of the environmental test chamber while exposing the product under test to pressure approaching 1 x 10-5 Torr. By combining Spark3D simulations and altitude testing, MtronPTI enhances the probability of mission success.

MtronPTI space-level products comply with ANSI/AIAA S-142-2016, Standard/Handbook for Multipactor Breakdown Prevention in Spacecraft Components.

Contact:

D.P. Devineni

MtronPTI

(407)298-2000 X:2194

Downloads:

Note 1 : MtronPTI’s extensive in-house test capabilities include Thermal Shock per MIL-STD-202, Method 107 • Terminal Strength per MIL-STD-202, Method 211 • Mechanical Shock per MIL-STD-202, Method 213 • Gross Leak Testing per MIL-STD-202, Method 112 • Random Vibration per MIL-STD-202, Method 214A • Fine Leak Testing – Helium per MIL-STD-202, Method 112 • Sinusoidal Vibration per MIL-STD-202, Method 201 and 204 • PIND (Particle Impact Noise Detection) per MIL-STD-202, Method 217 • Other Miscellaneous Testing including: Life, Immersion, Humidity, Barometric Pressure, Solderability • Dielectric Withstanding Voltage, Insulation Resistance, RF Testing 100 kHz to 40 GHz.

Spark3D is a product of Dassault Systems